Carbon fiber lamination service

Professional Carbon Fiber Lamination: 10 Years of Experience and Thousands of Completed Projects for Luxury Vehicles

10

Years of experience

11000+

Satisfied clients

3

Branches

150+

Top-tier professionals

Carbon fiber lamination service

Carbon fiber isn’t just a stylish tuning element; it’s a modern material that strengthens car parts and protects them from damage.

Carbon fiber lamination involves applying carbon fiber to individual car parts. In this process, the carbon fiber is coated with multiple layers of resin, which are then covered with a special automotive clear coat and polished. The entire procedure is carried out according to a step-by-step installation technical guideline.

Advantages of Carbon Fiber Lamination

-

Reinforcement of Parts: The carbon layer adds extra rigidity and strength to existing car components.

-

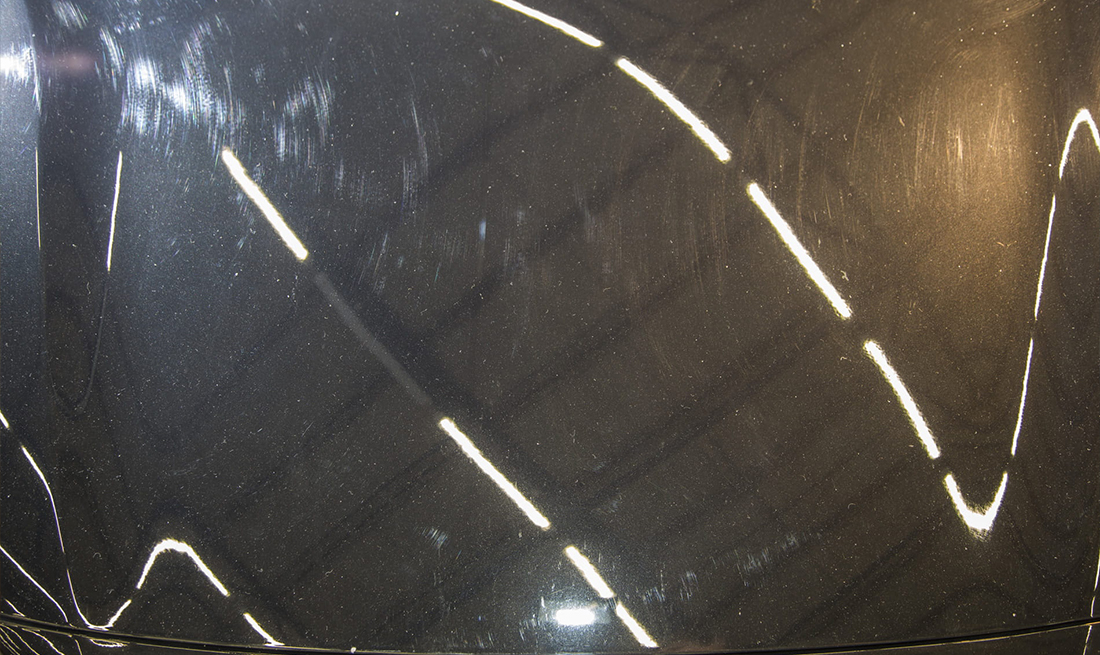

Surface Protection: Lamination protects parts from chips, scratches, and exposure to harsh chemicals. The surface becomes more resistant to damage.

-

Reversibility: If needed, the carbon coating can be removed, restoring the parts to their original condition without damage.

-

Maintaining Geometry: The lamination process does not alter the shape or size of the parts, preserving original gaps and mounting points.

-

Stylish Appearance: The carbon fiber texture gives parts a sporty look and makes the car stand out from the crowd.

Why Choose Us

With experience since 2016, we handle the full cycle, from sketch to finished product. Our specialists have over 10 years of experience in the composite industry. Today, we are ready to offer a complete range of design and manufacturing services for carbon fiber products. Our team includes some of the best experts in automotive tuning. We produce complex configurations, including large-scale pieces, and also work on custom orders.

Work stages

01

Surface preparation of the part

Surface cleaning from dirt, old coatings, and degreasing. At this stage, the part is sanded to improve the adhesion of the carbon fiber to the surface.

02

Primer application

The part is coated with a primer to enhance adhesion between the surface and the carbon fiber, as well as to prevent the formation of air bubbles beneath the carbon.

03

Adhesive application

A special adhesive (epoxy or polyester) is applied to the surface of the part to secure the carbon fiber.

04

Carbon fiber (fiberglass) layup

The carbon fiber is carefully applied to the part, smoothed out, and shaped to fit the required form. It’s important to avoid wrinkles and air bubbles.

05

Air removal

The carbon fiber is rolled with a roller or a vacuum is used to remove air and ensure a tight bond between the carbon and the part.

06

Second resin layer application

After the carbon fiber is laid, a second layer of resin is applied to fully saturate the fiber and achieve the desired coating thickness.

07

Vacuum bagging

In some cases, the part is placed in a vacuum bag to improve the lamination quality, ensuring better layer contact and preventing air bubbles.

08

Polymerization

The laminated part is placed in an oven for resin curing. The process can take from several hours to a full day, depending on the type of resin and curing conditions.

09

Sanding and polishing

After polymerization, the surface is sanded to remove any imperfections and prepare it for the final coating. Then, the surface is polished to achieve a smooth, glossy finish.

10

Applying a protective coating (clear coat)

The final step is applying a clear coat or protective layer to ensure durability, UV protection, and to give the part an aesthetic shine.

FAQs

01

What are the advantages of carbon fiber lamination compared to painting?

Carbon fiber lamination gives parts a unique appearance, enhances durability, and provides better resistance to chips and scratches. It is also highly heat-resistant and long-lasting compared to traditional paint.

02

Can any car part be laminated with carbon fiber?

Most car parts can be laminated with carbon fiber, including body panels, mirrors, spoilers, and interior elements. However, the surface must be suitable for proper adhesion, and the part should be able to withstand the heat treatment process.

03

How long does carbon fiber lamination last?

With proper use and care, carbon fiber lamination can last for many years. It is resistant to weather conditions, UV exposure, and minor mechanical damage, especially when a protective coating is applied and the surface is kept clean.